NEWS AND

INFORMATION

Return

Return

In the morning of July 11, in the conference room on the 11th floor of Duowei headquarters, a FM training organized by the technology center was held. This training invited Huang Ziyang, the head of FM certification (Hong Kong), and the chief engineer from the U.S. headquarters. The FM Certificate is universally recognized worldwide and tells the consumer that the product or service has been tested to the highest U.S. and international standards. This shows the importance of FM certification in the industry. At present, Duowei has obtained FM certification in many projects such as DW-19 metal roofing system, metal curtain wall energy-saving sandwich panel system and D36, etc. The company is leading the industry by virtue of its product quality and excellent construction technology.

What is FM certification?

Founded in 1835, FM GLOBAT is now the world's number one industrial and commercial property insurer. Headquartered in the United States, FM provides testing and certification services for industrial and commercial products worldwide through its affiliated FM APPROVALS organization. The FM Certificate is universally recognized worldwide and tells the consumer that the product or service has been tested to the highest U.S. and international standards.

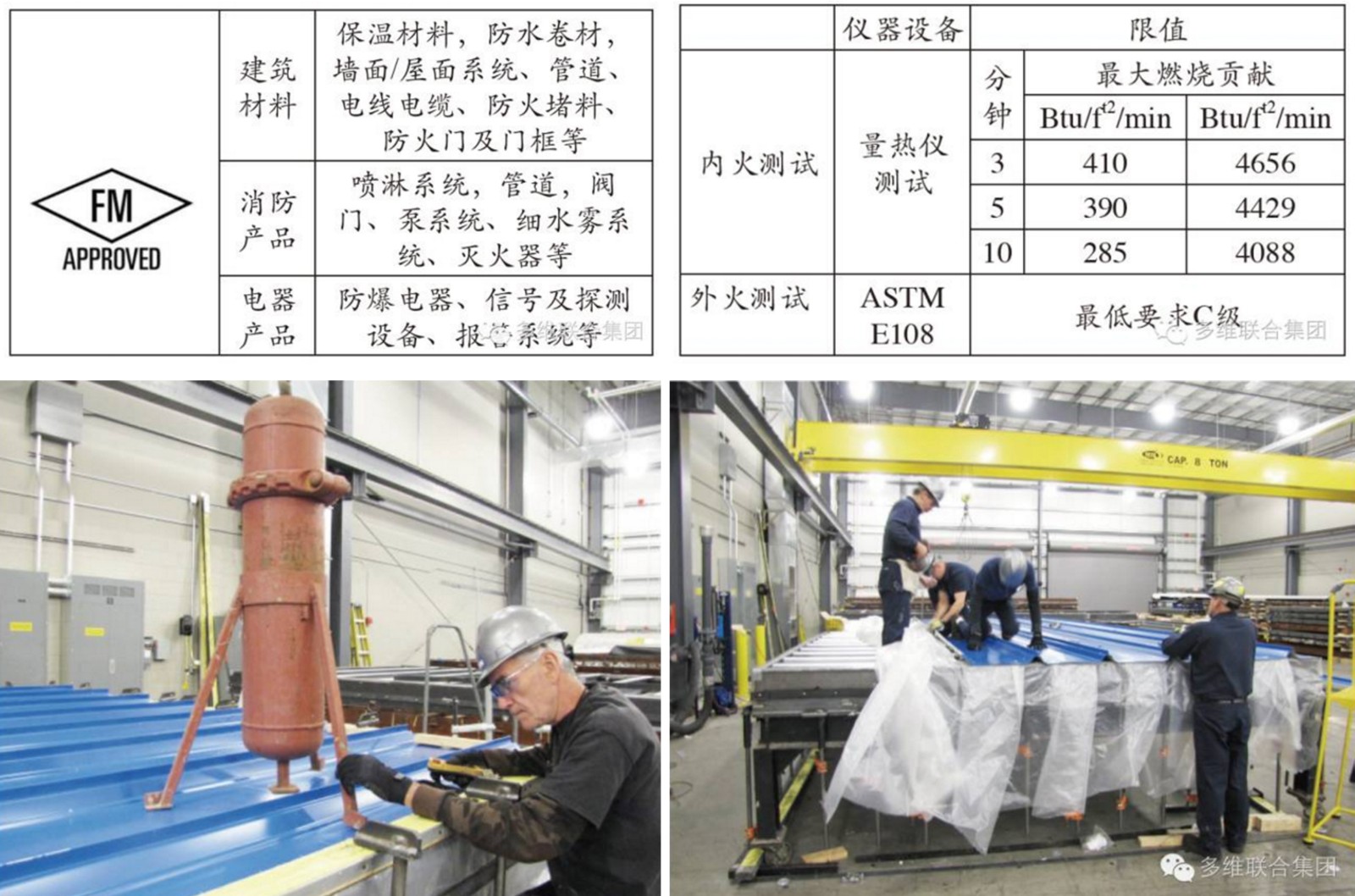

FM certified products are not all-inclusive, but are clearly targeted at the following areas that are closely related to property safety:

How does FM certify color steel roofing systems?

The color steel roofing system is covered within the scope of FM certification, and the certification is based on the FM4471 APPROVAL STDS FOR CLASS 1 ROOF PANELS. The standard describes the performance requirements of roof panels for internal fire rating, external fire rating, wind rating, hail rating, and trampling resistance. Roofing panels pass the test under the conditions required by this standard are considered to meet the Class 1 requirements -CLASS 1 PANEL ROOFS. M4471 certification tests include flame test, simulated wind uplift, trampling resistance test, as well as hail resistance and water leakage tests, and are mainly completed in the fire laboratory and natural risk laboratory.

The Class FM4471 flame test is based on the roofing fire test requirements of ASTM E108 and is divided into three categories, Class A, Class B, and Class C, based on the presence or absence of combustible material on the lower surface of the roofing panels. The minimum level for certification is Class C. Roof coverings and substrates must be able to resist against low-grade fire hazards and "provide protection for roof panels against low-grade fire". ASTM E108 flame test: 10 minute flame spread test under 12MPH (5.4M/S) wind speed and 1400F (760C) maximum flame spread.

The wind resistance test is performed on a 12FT*24FT (3.7M*7.3M) sample on a wind uplift test bench, and an inflated sealed air bag is set under the roofing panel to provide pressure required. Apply positive pressure to the bottom of the roof, starting at 60 PSF (2.9 KPA) and holding 60 SPF (2.9 KPA) for one minute. If the roofing system can last more than one minute under steady pressure then the sample is deemed to pass the corresponding pressure rating, then increase the pressure by 15 PSF (0.7 KPA) each time until the sample is damaged. The last rating before failure is the highest wind resistance rating acceptable by the roofing system as determined by FM.

All FM certified roofing systems will at least has FM 1-60 rating, the minimum rating certified by FM. Between each rating is an increase of 15 PSF, for example: 1-75, 1-90, 1-105, etc., up to a maximum of 1-990. The current light steel structure building roofing systems in China involves more wind resistance level requirements from 1-60 to 1-180, as shown in the following table:

Safety factor

FM uses a safety factor of 2.0 to include the wind resistance rating of the roof into the wind resistance design value, which will result in an actual safety factor greater than 2.0 for most roofs. For example, if the design load of a roof panel is 35PSF (1.7KPA), FM requires a wind resistance rating of 1-90, means a safety factor of 2.57. The FM4471 standard is based on FM tests, research and testing, considering the recommendations of manufacturer, users and loss control experts. FM focuses on enclosure systems when it comes to wind resistance design, especially roofing system, which is co-determined by including roof panels, roof purlins, connectors and their reliable connections.

The trampling resistance test requires the roof assembly to resist trampling being confirmed. There should be no perforation on the surface of the panel, and no detachment or loosening between adjacent panels or edge panels. Apply a 200 lb load to the roof panels and repeat at least 4 times.